This guide explores the details of QR codes for inventory management.

While barcodes have served us well, they have limitations, such as lower data capacity, error proneness, and the need for specialized scanners.

QR codes overcome these challenges, and we'll observe them through.

What is a QR Inventory System?

A QR (Quick Response) inventory system is a digital leap in stock management using advanced QR code technology.

📲 More than just sophisticated barcodes, QR codes hold tons of data about their attached items and connect to digital platforms like websites or apps.

QR codes simplify inventory management. Instead of manual entry or outdated software, you can scan the codes with a smartphone or scanner to get item information instantly.

📦✅ Real-time tracking, easy stock level monitoring, and automatic updates make QR systems time-saving, efficient, and cost-effective.

How Does the QR Code Inventory System Function?

Now that we understand what a QR inventory system is let's explore how it operates in your inventory management workflow.

- Label establishment: At the onset of inventory management, each item or batch in your inventory is assigned a unique QR code. This code carries many information such as item name, SKU number, location, price, etc.

- Scanning: The next step involves scanning the QR codes. You can simply use a smartphone or a QR code scanner for this process.

- Data Filtering: Upon scanning, the QR code retrieves all the data associated with that particular inventory item, eliminating the need for manual entry or searching.

- Updating Inventory Data: The beauty of using QR codes for inventory management resides in real-time updates. Once an item is scanned, the inventory levels automatically update across the entire system.

- Reporting: Since every transaction or move is recorded, QR codes help generate extensive reports, providing comprehensive insight into your inventory.

With the growing adoption of QR code inventory systems, many businesses are already enjoying streamlined operations.

Benefits of Using QR Codes for Inventory Management

In the quest to reduce inefficiency and drive technological innovation, several businesses—including inventory management—are undergoing a shift. What is the shift in question?

The shift from traditional barcodes to QR codes. But why exactly should you consider using QR codes for inventory management?

QR Codes Occupy Less Space, Speeding Up The Inventory Process

QR codes are compact and can contain a myriad of information. These can be easily affixed to a tiny component of an inventory item, no matter how small it is. This, in turn, speeds up the inventory process immensely and ensures efficient stock management.

Easy to Scan & Damage Resistant with Minimum Error Correction Levels

QR codes can be scanned from any angle, making the scanning process efficient and quicker. Plus, they have excellent damage resistance - meaning even if a part of the code is damaged, the remaining data can still be comprehended accurately.

Real-time Asset Tracking with a QR Code-Based Inventory Management System

A QR code inventory system allows real-time tracking of all the inventory items. Each time a QR code is scanned, it updates the inventory data in real time, keeping track of the product's location, status, and other details—contributing to seamless inventory management.

Integrating QR Codes into Current Product Inventory Systems

QR codes can be easily integrated into an existing inventory system. QR codes can be leveraged to enhance their efficiency without requiring a major overhaul of your current system.

Utilizing Cloud Technology with QR Code Systems

One of the major perks of QR codes is that they can be tied to cloud-based inventory management systems. This means that all the data associated with the QR code is stored in the cloud and can be accessed anywhere. This feature provides you with complete control over your inventory, irrespective of your location.

How to Use & Set Up QR Codes for Inventory Management?

By now, you're probably intrigued by how QR codes can revolutionize your inventory management.

But how do you go about implementing them?

This section is designed to guide you step by step, covering everything from creating and printing your first QR code to integrating it into your existing inventory management system.

Creating and Printing QR Codes

Creating and printing your own QR codes is straightforward, regardless of your technical know-how. While there are myriad QR code generators to choose from, it's crucial to opt for one that supports all the features you need. Here's how:

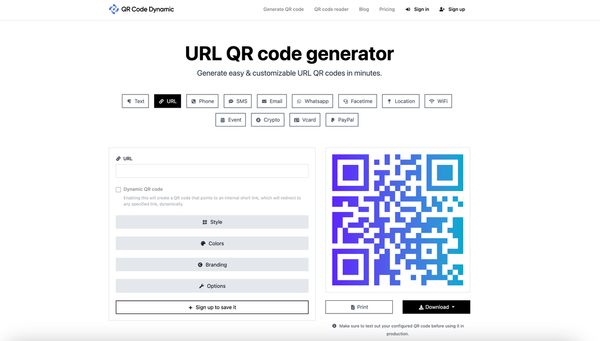

Choose a QR code generator: Find a reliable QR code generator online. Look for one that supports bulk creation for ease and efficiency. You can use QR Code Dynamic to create dynamic QR codes for inventory management.

Input information: Once you've finalized your generator, you need to input the necessary information or data into the tool. This could be a website URL, text block, or product-specific data.

Generate the QR codes: Hit the 'Create' button and let the tool work its magic. The result will be an array of QR codes unique to the information provided.

Download the QR codes: Post-generation, download the QR codes. They will usually be saved in a universal format, like .png or .jpg, or a ZIP file with each QR Code as a separate file.

Creating Trackable QR Codes

Creating trackable QR codes follows the same process mentioned above. However, additional parameters are added to collect data whenever the code is scanned. Depending on your needs, this data can then be used for marketing purposes, tracking the supply chain, membership management, and other purposes.

Follow the above-mentioned steps with the addition of one more step—enable the tracking feature in the chosen QR code generator. This will allow analytics to be extracted from each scan.

After creating your QR codes, it's time to print them. You can use a regular printer for this. Depending on where you plan to affix the codes to your inventory items, opt for labels or sticker paper.

Integrating QR Codes into Your Inventory Management System

After generating and printing the QR codes, next comes their integration into your existing inventory system. Here's how:

- Assign Codes: Begin by assigning each QR code to a specific item or batch in your inventory. The specifics of this process will depend on your inventory management software, but in general, you will need to enter the product's information and the corresponding QR code.

- Affix the QR codes: Next, print out the QR codes and affix them to the appropriate items in your inventory. Make sure they're firmly attached and conveniently positioned for easy scanning.

- Training: Provide necessary training to your employees to familiarize them with using a QR Code scanner or mobile device to scan the codes and access the inventory data.

- Test the System: Test your QR code system to ensure everything runs smoothly. This entails running real-life scenarios through the system to ensure it can handle everyday activities.

- Real-time Data Update: One of the major advantages of QR codes is real-time data updating. Make sure you've set up your system to do this. When a product's QR code is scanned, the system should automatically adjust the inventory counts and locations accordingly.

Practical Applications of QR Codes for Inventory Management

Now that we've spent some time setting up your QR code inventory system let's take a look at some specific, practical applications. QR codes can transform key areas of inventory management, making your life easier while ensuring your operations remain efficient and on track.

Bulk QR Codes & QR Code API for Inventory Management

One of the greatest benefits of QR codes is their ability to work in bulk. When managing an inventory, dealing with individual items can be a tedious process. But with QR codes, you can streamline a good portion of these tasks.

- Bulk QR Codes: Instead of creating QR codes individually, you can generate them in bulk. Bulk QR code generation can handle whether you're dealing with a hundred items or tens of thousands. Each code still contains unique information about the item it's linked to, so there's no need to worry about mix-ups or errors.

- QR Code API: Using a QR code API allows you to automate the creation and application of QR codes in your system. This alleviates manual workload and enables QR codes to fit seamlessly into your current processes. APIs also allow for the easy creation of trackable QR codes. These codes not only contain information about the item but can keep a log of every time they're scanned, providing ample data about your inventory's movements.

Streamlined Stocktaking With QR Labels

Stocktaking is often viewed as a necessary evil in inventory management. It's time-consuming and monotonous but vital for keeping your operations running smoothly. This is another area where QR codes can help.

With QR labels, you can expedite the process significantly. Instead of manually counting items, all it takes is a quick scan. The scanner would instantly pull up the necessary data about the item, such as its count. You can even verify this against your system's records, allowing for error checking and correction on the go.

Order Fulfillment & Seamless Chain of Custody with QR Codes

Yet another key aspect of inventory management is order fulfillment and maintaining the chain of custody. QR codes can streamline this in various ways.

- Fast and Accurate Picking: Pickers can scan the QR code of each item they pick, with the system immediately checking off that item from the order list. This reduces instances of mistaken picks while making the process quicker.

- Easy Packing & Shipping: Similarly, packers can scan the items they're packing, enabling real-time updating of the order status right up until it's shipped off.

- Chain of Custody Traceability: QR codes can help maintain a seamless chain of custody once the order has left your premises. Each time the order changes hands, the QR code can be scanned. This leaves an electronic trail that can be traced back if needed, providing transparency and promoting accountability.

Managing and Maximizing Efficiency in Inventory with QR Codes

The overarching utility of QR codes lies in how they can boost overall efficiency in managing your inventory.

They provide a significant degree of automation, minimizing manual procedures and thereby reducing potential errors. Real-time updates mean you're always in the loop on your stock levels and movements, enabling smarter, more accurate decision-making.

Moreover, QR codes simplify processes across the board. Whether stocktaking, order fulfillment, or general inventory management, QR codes save time and effort, letting you and your team focus on other essential tasks.

Innovative Techniques in QR Code Inventory Management

In today's fast-paced, technology-driven world, innovation is key to keeping your inventory management methods nimble, efficient, and up-to-date.

Despite their simplicity, QR codes can be employed innovatively to add significant value to your business techniques.

In this section, we'll delve into some intriguing ways to make the most of QR codes, from making them work in all scenarios to using them as a customer touchpoint.

Making QR Codes Work Everywhere

QR codes can transcend inventory management and offer value in a plethora of scenarios, proving to be a versatile tool for your business. Here's how:

- QR Code and GPS: By pairing QR codes with GPS tracking, you can easily keep tabs on items that frequently move locations. When an item's QR code is scanned, it can automatically sync with a GPS system, giving you the exact current position of your assets.

- QR Codes for Maintaining Equipment: You can also use QR codes to ensure your equipment stays in its top shape. By assigning a QR code to each piece of equipment, you can store all significant details about that equipment – like the purchase date, service records, last maintenance date, and more. Any maintenance staff can scan the code to access such information before servicing, ensuring optimal care.

- Inventory Control in Multiple Locations: Have multiple branches or stores? QR codes can make inventory transfers a breeze. Scanning a QR code when an item leaves one location and scanning it again upon reaching the new location can automate transfer recording. Not only does it save on paperwork, but it also ensures consistency by preventing human errors.

Companies Incorporating QR Codes in Their Systems

Many companies have enthusiastically embraced the shift to QR code-based inventory management and are reaping very satisfying benefits. Here's how they're using it:

- E-Commerce Businesses: Such companies are using QR codes for virtually every step of their operation, from inventory management and tracking to customer interactions. QR codes on packaging can contain product information, user manuals, or even links to video tutorials, providing superior customer experience.

- Restaurants and Supermarkets: Paper menus or manually updating stock levels are passé. Now, eateries and grocers use QR codes for digital menus and automate stock updates. Customers scan a QR code and can easily check available options without the need for waitstaff or walking through aisles.

- Warehouses: QR codes have simplified warehouse management significantly. With codes on bins, shelves, and individual items, personnel can keep track of what's stored where and in what quantity.

Conclusion

In conclusion, QR codes are pivotal in inventory management, adding efficiency and accuracy to businesses of all sizes.

Their capacity to store vast amounts of data, ease of scanning, real-time tracking, and seamless integration into existing systems make them practical tools for modern inventory management.

Notably, the alignment with cloud technology facilitates global accessibility while simplifying bulk inventory tracking with QR codes.

Frequently Asked Questions

Can QR codes be used to track inventory in multiple locations?

Yes, QR codes can be used to track inventory across multiple locations. Each code can contain information about the item's current location, and scanning the code can update the central inventory database with this information, ensuring accurate tracking and management across all sites.

How can QR codes help in reducing inventory shrinkage?

QR codes help reduce inventory shrinkage by providing accurate and real-time tracking of items. This visibility allows for better monitoring of stock levels and movements, reducing the likelihood of theft, misplacement, and administrative errors.

How do QR codes facilitate inventory audits?

QR codes facilitate inventory audits by allowing for quick and accurate scanning of items. Auditors can scan each item's QR code to verify its presence and update the inventory records, significantly speeding up the auditing process and improving accuracy.