The barcode inventory system is a crucial tool for modern commerce, streamlining inventory management via barcodes.

Through rapid scanning and logging of product details, it enhances efficiency and accuracy across product lifecycles.

Here is a detailed walkthrough of the barcode inventory system.

What is a Barcode Inventory System?

A barcode inventory system is a technology-based solution that utilizes barcode labels and scanners to efficiently manage and track inventory items.

At its core, this system assigns a unique barcode to each item in your inventory.

When these barcodes are scanned using a barcode scanner, the data is instantly recorded and updated in a centralized database.

Key Components of a Barcode Inventory System:

- Barcodes are unique identifiers printed on labels and attached to each inventory item. They can be in various formats, such as UPC, EAN, or QR codes.

- Barcode Scanners: Devices read the barcodes and transmit the information to the inventory management software. These can be handheld or fixed scanners.

- Inventory Management Software: The system's backbone, this software processes the data collected from the barcode scanners, updating inventory levels in real time and providing valuable insights into stock movements.

How Does a Barcode Inventory System Work?

A barcode inventory system works by automating the process of tracking and managing inventory items through the use of barcode labels and scanners.

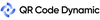

Here’s a step-by-step breakdown of how it functions:

1. Labeling Items with Barcodes:

Each inventory item is assigned a unique barcode, which is printed on a label and affixed to the item. These barcodes contain essential information such as product ID, description, and price.

2. Scanning Barcodes:

When an inventory item is added, moved, or sold, a barcode scanner is used to read the barcode. Scanners can be handheld, mobile, or fixed, depending on the needs of the business.

3. Data Transmission:

The scanner reads the barcode and transmits the data to the inventory management software. This transmission can be done via wired or wireless connections.

4. Updating the Inventory Management Software:

The inventory management software processes the scanned data, updating the inventory records in real time. This ensures that the database reflects the current status of each item, including quantities and locations.

5. Real-Time Inventory Tracking:

As items are scanned during various stages like receiving, moving, or shipping, the software continuously updates the inventory levels. This real-time tracking helps businesses maintain accurate stock counts and avoid issues like overstocking or stockouts.

6. Generating Reports and Insights:

The system can generate detailed reports and provide insights into inventory movements, helping businesses analyze trends, forecast demand, and make informed decisions about purchasing and stock management.

Example Workflow:

1. Receiving Inventory:

- Items are delivered, and each barcode is scanned.

- The software records the new items and updates the stock levels.

2. Managing Inventory:

- As items are moved within the warehouse, their barcodes are scanned to update their locations in the system.

- This helps in quickly locating items when needed.

3. Fulfilling Orders:

- When items are picked for orders, their barcodes are scanned.

- The system deducts these items from the inventory and updates the stock levels.

4. Shipping Products:

- Before shipping, items are scanned to confirm the correct products are being sent.

- The system records the shipment and updates the inventory accordingly.

By automating these processes, a barcode inventory system enhances accuracy, efficiency, and visibility in inventory management, making it a vital tool for businesses of all sizes.

Benefits of the Barcode Inventory System

Implementing a barcode inventory system offers numerous advantages that enhance the efficiency and accuracy of inventory management.

Here are the key benefits:

How to Implement the Barcode Inventory System

Implementing a barcode inventory system involves several steps to ensure smooth integration and efficient operation.

Here is a step-by-step guide to help you implement the system effectively:

Step 1: Assess Your Inventory Management Needs

- Evaluate Current Processes: Understand your current inventory management processes and identify areas that need improvement.

- Define Objectives: Determine what you want to achieve with the barcode inventory system, such as increased accuracy, efficiency, or better inventory visibility.

Step 2: Choose the Right Barcode System

- Select Barcode Types: Choose the appropriate barcode format (e.g., UPC, EAN, QR codes) based on your inventory items and industry standards.

- Pick Barcode Scanners: Decide on the type of barcode scanners (handheld, mobile, fixed) that best suit your operational needs.

- Select Inventory Management Software: Choose software that integrates well with your existing systems and meets your inventory management requirements.

Step 3: Plan the Implementation

- Create an Implementation Plan: Develop a detailed plan outlining the steps, timeline, and resources needed for implementation.

- Allocate Budget: Determine the budget for purchasing hardware (scanners, printers), software, and training.

Step 4: Design and Print Barcodes

- Design Barcodes: Create barcode labels with all necessary information, ensuring they are easy to scan and read.

- Print Barcodes: Use a barcode printer to produce high-quality barcode labels for your inventory items.

Also see: How to Use QR Codes for Print Media to Maximize Engagement

Step 5: Label Inventory Items

- Affix Barcodes: Attach barcode labels to each inventory item, ensuring they are placed in accessible and visible locations for easy scanning.

Step 6: Set Up Hardware and Software

- Install Barcode Scanners: Set up and test barcode scanners in the locations where they will be used.

- Install Inventory Management Software: Install and configure the inventory management software, ensuring it is integrated with your existing systems.

Step 7: Train Employees

- Conduct Training Sessions: Train employees on how to use barcode scanners and inventory management software. Ensure they understand the new processes and their benefits.

- Provide User Manuals: Offer user manuals and support resources to help employees adapt to the new system.

Step 8: Test the System

- Run Pilot Tests: Conduct pilot tests to ensure the barcode inventory system works correctly. Scan barcodes, update inventory records, and verify data accuracy.

- Resolve Issues: Identify and address any issues or challenges encountered during the testing phase.

Step 9: Go Live

- Launch the System: Roll out the barcode inventory system across your entire operation.

- Monitor Performance: Continuously monitor the system's performance, gathering feedback from users and making necessary adjustments.

Step 10: Maintain and Update the System

- Regular Maintenance: Perform regular maintenance on barcode scanners and software to ensure optimal performance.

- Update Barcodes and Software: Keep barcodes and software updated to accommodate changes in inventory and technological advancements.

- Ongoing Training: Provide ongoing training for new employees and refreshers for existing staff to ensure everyone stays proficient with the system.

How to Set up a Barcode System for Small Businesses

→ Step 1: Assess Your Needs: Identify the specific inventory management needs and objectives of your small business to determine the best barcode system setup.

→ Step 2: Choose the Right Tools: Select suitable barcode formats (e.g., UPC, EAN, QR codes), handheld scanners for easy use, and user-friendly inventory management software that integrates with your existing systems.

→ Step 3: Plan Your Implementation: Develop a realistic implementation timeline and allocate a budget for purchasing necessary hardware, software, and training.

→ Step 4: Design and Print Barcodes: Create barcodes with essential product information and use a high-quality printer or service to produce durable barcode labels.

→ Step 5: Label Your Inventory: Attach barcode labels to all inventory items in consistent and accessible locations for easy scanning.

→ Step 6: Set Up Hardware and Software: Install barcode scanners at key points in your business, such as checkouts and storage areas, and configure the inventory management software to integrate with the scanners.

→ Step 7: Train Your Staff: Conduct training sessions to educate employees on using the barcode scanners and inventory management software and provide user manuals for reference.

→ Step 8: Test the System: Run a small-scale test to ensure the system functions properly, making any necessary adjustments based on feedback.

→ Step 9: Launch the System: Roll out the barcode system across your entire business, continuously monitoring its performance and gathering feedback from users.

→ Step 10: Maintain the System: Perform regular maintenance checks on barcode scanners and software, keep software updated, and provide ongoing training for staff to ensure smooth operation.

What to Consider When Creating a Barcode Inventory System

Select the Right Barcode Format– UPC, EAN, QR codes, Software compatibility

Invest in Quality Equipment– Reliable barcode scanners, High-quality barcode printer

Choose Appropriate Software– User-friendly and scalable, Integration with existing systems

Plan for Integration– Smooth data transfer, Compatibility with other business systems

Design Durable Barcodes– Easy-to-scan and informative, Durable materials

Ensure Proper Label Placement– Consistent and accessible locations

Train Your Staff– Comprehensive training, Ongoing support

Conduct Pilot Testing– Identify and fix issues, Gather feedback

Monitor and Maintain the System– Regular checks and updates, Optimal performance

Evaluate Cost-Benefit– Analyze costs vs. benefits, Align with business goals

Plan for Future Scalability– System growth with business, Future expansion features

To Conclude

In conclusion, the barcode inventory system offers strategic benefits for businesses keen on improving their inventory control.

Delivering efficient operations and enhanced customer service is more than a necessity; it's a key competitive edge.

Now that you’ve covered the barcode inventory system and details that can help. We hope you can benefit from it.

Frequently Asked Questions

What types of businesses benefit most from using a barcode inventory system?

Retailers, warehouses, manufacturers, and logistics companies benefit the most from barcode inventory systems due to the high volume of items they manage and the need for efficient tracking and accuracy.

Can a barcode inventory system help in reducing theft and loss?

Yes, a barcode inventory system helps in reducing theft and loss by providing precise tracking of inventory movements and maintaining accurate records of stock levels.

What are the common challenges faced when implementing a barcode inventory system?

Common challenges include initial setup costs, employee training, integration with existing systems, and ensuring consistent barcode label quality and placement.

What role does mobile technology play in modern barcode inventory systems?

Mobile technology allows employees to use handheld devices to scan barcodes, access inventory data on the go, and perform inventory tasks remotely, increasing flexibility and efficiency.

Visit our other blog posts: