QR codes have moved far beyond restaurant menus—today they’re a low-cost bridge between print and digital that any brand can deploy overnight. In my role as a marketing specialist, I’ve watched even the smallest businesses boost engagement by 20–40 % simply by adding a scannable code to flyers or packaging. Yet I still see confusion about how to get from a crisp digital design to a reliably scannable print.

In this guide we will break down every step, from picking a QR code generator to choosing paper stock. In Part 1, I’ll clarify why printing QR codes matters and set you up with the foundational knowledge you need to avoid costly misprints. In Parts 2 and 3, we’ll dive into design tweaks, printing techniques, and performance tracking—so you can turn those little squares into measurable ROI.

Understanding Printing QR Codes

Importance in Marketing

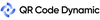

Before we touch a printer, it’s worth zooming out. QR codes convert passive surfaces into interactive gateways, letting customers jump straight to coupons, how-to videos, or in-store apps without typing a single URL.

- Drive instant engagement. A single scan transports users from offline to online, shortening the funnel and trimming cart abandonment.

- Track offline ROI. Paired with UTM codes or short-link redirects, scans reveal which postcards, posters, or product labels actually convert.

Upgrade customer experience. Interactive manuals, warranty look-ups, or immersive AR demos live one tap away, slashing support tickets.

- Boost brand perception. A well-designed, flawlessly scanning code signals tech-savvy credibility—especially to Gen Z.

Creating Your QR Code

Designing a QR code that scans in a split-second and looks on-brand starts long before ink touches paper. I’ve learned that every successful print campaign begins with the right generator and thoughtful design choices. Skip these fundamentals and you risk ending up with a beautiful—but unreadable—square on your brochure. In this section, I’ll share exactly how I vet tools, tweak visuals, and validate codes before they ever leave the screen.

Choosing the Right QR Code Generator

A generator is more than a “make a square” button—it dictates security, analytics, and update flexibility down the road.

- Feature depth matters. Look for dynamic URL editing, track analytics, and error-correction settings.

- Compatibility counts. Ensure export formats (SVG, EPS, high-res PNG) match your print shop’s requirements.

- Pricing versus scale. Freemium works for one-off flyers; ongoing campaigns usually need a paid tier with API access.

Designing Your QR Code

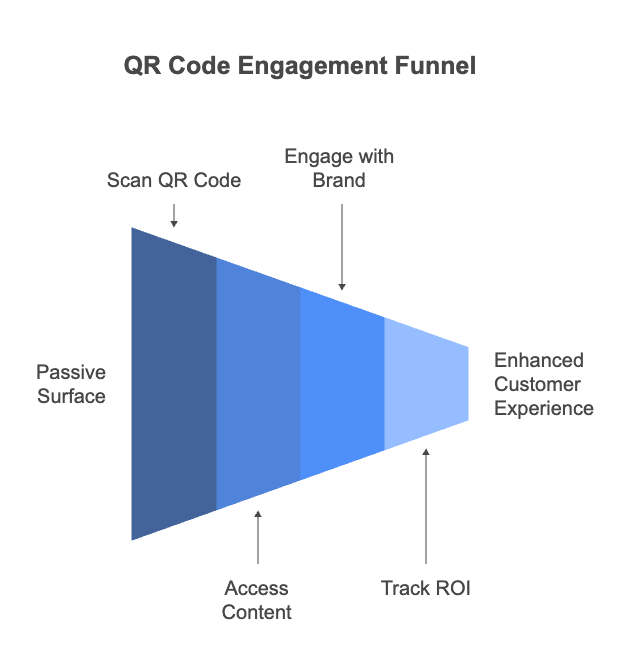

Even a top-tier generator can’t save you from poor design decisions. In my experience, most of the failed scans trace back to over-stylized codes.

- Stay high-contrast. Dark foreground on a light background—avoid pastels on pastels.

- Mind the quiet zone. Leave a blank border equal to four modules (tiny squares) on all sides.

- Embed logos cautiously. Keep the logo < 30 % of total area or risk masking key finder patterns.

- Test at multiple sizes. Size of the QR Code matter. Print a draft at actual size; scan from ~25 cm away to mimic real-world use.

Printing QR Codes

Printing is where “almost right” turns into “totally wrong” if you overlook materials or resolution. This section walks through method selection, material choices, and real-world troubleshooting so your codes scan flawlessly straight off the stack.

Selecting the Right Printing Method

Different print technologies handle QR detail differently. Choose based on volume, budget, and finish quality.

- Digital laser/inkjet:

- Best for <1 000 units and variable data (unique codes).

- Typical resolution: 600–1 200 dpi—sufficient for codes ≥10 mm.

- Offset lithography:

- Ideal for >1 000 units and Pantone accuracy.

- Needs vector (EPS/PDF) files; watch dot gain on uncoated stock.

- Thermal QR barcode printer / QR code label printer:

- Perfect for industrial stickers and packaging lines.

- Direct thermal fades in sunlight; choose thermal-transfer for longevity.

Printing Techniques and Materials

Durability and clarity hinge on substrate and finish.

- Paper weight: 200–300 gsm for postcards; lighter stock risks curl that distorts modules.

- Coatings:

- Matte reduces glare, improving scan reliability under harsh lighting.

- Gloss UV adds pop but can cause reflections—test before full run.

- Sticker media: Vinyl with waterproof laminate for outdoor use; choose permanent adhesive for shipping boxes.

Troubleshooting Common Issues

Even with perfect files, real-world hiccups happen. Here’s my quick-fix checklist:

- Blurry prints? Verify printer set to “photo” or “high-quality” mode; low-res drafts cripple edges.

- Code too small? Minimum size = 1 cm × 1 cm per 30 cm scanning distance.

- Dark blobs in modules? Clean inkjets/plates; excess ink bleeds create false positives.

- Refuses to scan on curved surfaces? Increase code size 20 % and use flexible vinyl.

Integrating QR Codes into Your Marketing Strategy

For many brands, printing QR codes is the easy part—knowing where to place them and how to prove they actually work is where campaigns either shine or stall. In my day-to-day life as a marketing specialist, I’ve learned that thoughtful placement can raise scan rates and that disciplined analytics keep budgets honest. In this section, I’ll show you exactly where to stick those codes, how to track every tap, and what a year-long success story looks like in practice.

Placement and Visibility

A code that hides in plain sight won’t drive revenue. Use these field-tested tactics to put scannability first:

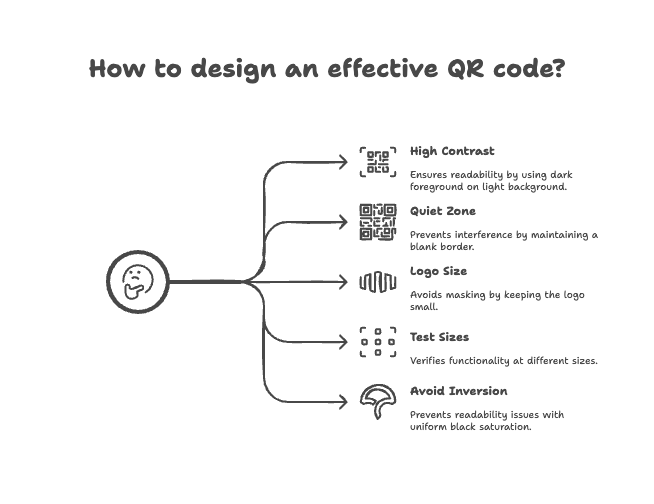

- Front-and-center real estate.

- Product packaging: front label for retail shelves, cap seals for consumables.

- Business cards: back side, minimum 15 mm square.

- Eye-level signage. Posters, point-of-sale displays, and shelf-talkers should sit between 90–150 cm from the ground for effortless phone alignment.

- Motion-friendly media. For buses, billboards, or event banners, oversize the code to at least 2 cm per meter of viewing distance—that’s a life-saving rule I picked up after a too-small transit ad flopped.

- Print QR code stickers as “bonus” add-ons for laptops or packaging inserts—customers love the novelty and tend to scan out of curiosity.

Measuring QR Code Effectiveness

Without data, you’re guessing. Here’s my proven tracking stack:

- Dynamic URLs + UTM parameters so every scan pings Google Analytics.

- QR platform dashboards for real-time scan heatmaps.

- Link shorteners when you need vanity links that are easy to share verbally.

- CRM integration to marry scans to lead status; I pipe events into HubSpot so sales sees who interacted at trade shows.

Final Thoughts and Conclusion

Printing QR codes isn’t just a production chore—it’s a strategic bridge that turns every brochure, label, or trade-show banner into a measurable conversion point. From my hands-on experience, I’ve seen brands of every size unlock richer customer journeys simply by pairing smart placement with rigorous analytics. Remember to match generator features to your goals, design for effortless scanning, and treat the print shop as a partner, not a vendor.

As you roll out your own codes, test early, track relentlessly, and iterate often.

❓ Frequently Asked Questions (FAQ)

1. What is the best way to create a scannable QR code for print?

To ensure your QR code prints clearly and scans instantly, use a high-quality QR code generator that supports dynamic URLs, SVG exports, and error correction. Avoid over-styling—stick to a high-contrast color scheme and test the final design by printing a draft. You can also explore QR code printing tips to match the right resolution and material for your campaign.

2. How do I track how many people scan my printed QR code?

Use dynamic QR codes combined with UTM parameters and Google Analytics to monitor performance. Platforms like QRCodeDynamic also offer built-in QR code tracking dashboards that show scan location, time, and device. To get the most reliable insights, assign different QR codes to each print batch for A/B testing.

3. What size should a QR code be for different print formats?

QR codes should be at least 1 cm x 1 cm for every 30 cm of scan distance. For flyers or packaging, 15–20 mm works well. For billboards, codes may need to be oversized—around 2 cm per meter of viewing distance. You can find more recommendations in our QR code printing guide and QR design best practices.

4. What materials should I use to print durable QR codes?

Use 200–300 gsm paper for flyers, matte finishes for indoor displays, and waterproof vinyl labels for outdoor use. For labels, consider using QR code stickers with permanent adhesive. Our guide on printing techniques and materials outlines what works best for different use cases, from product packaging to shipping boxes.

5. Can I use one QR code for multiple campaigns or updates?

Yes! With dynamic QR codes, you can update the destination URL even after printing. This is ideal for ongoing promotions, product launches, or seasonal content. You’ll save money on reprints and keep your campaign content fresh. Learn how to set this up in our step-by-step article on creating dynamic QR codes.